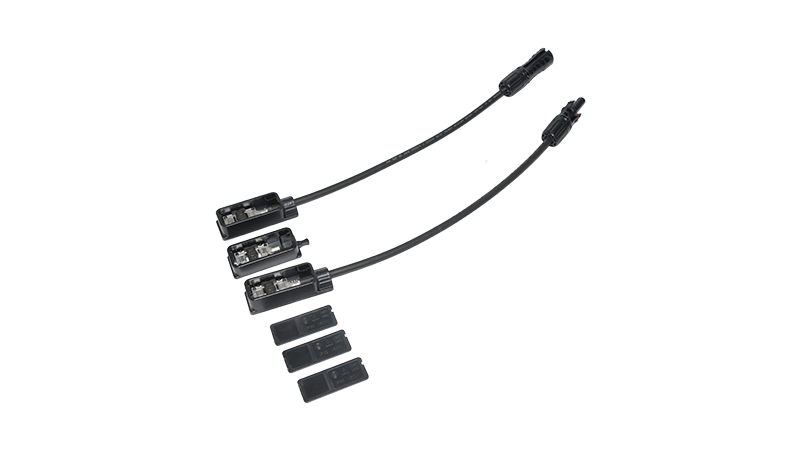

The solar photovoltaic junction box is used at the junction of the cable (or the corner of the cable tube) as a transition. The two cable tubes are connected with the junction box, the cable in the tube is connected in the junction box, and the photovoltaic junction box plays the role of protecting and connecting the cable.

Structure of photovoltaic junction box

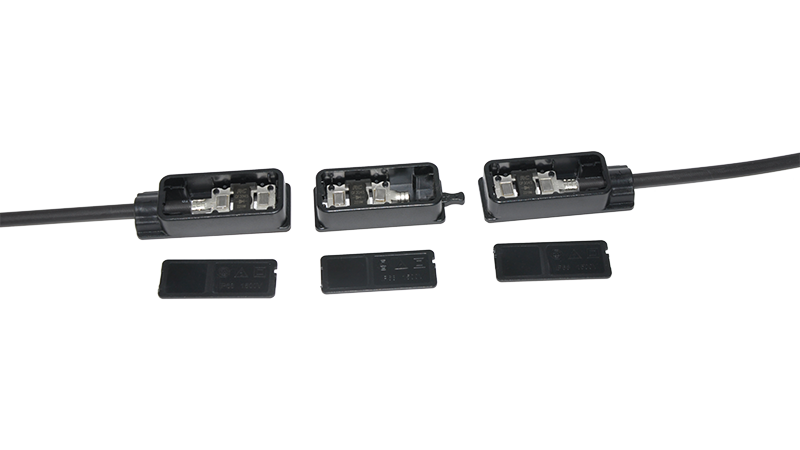

Body and cover of junction box

The base material of the box body and cover of the photovoltaic junction box is commonly PPO, which has the advantages of good rigidity, high heat resistance, non-combustible, high strength and excellent electrical performance. In addition, PPO also has the advantages of wear resistance, non-toxic, pollution resistance, good weather resistance and so on. The dielectric constant and dielectric loss of PPO is one of the smallest varieties of engineering plastics, and it is almost unaffected by temperature and humidity, so it can be used in the field of low, medium and high frequency electric fields.

Terminal

The input end of the terminal is connected to the bus bar of the solar panel, and the output end is connected to the cable. Terminals are generally made of pure copper or tinned copper. Tinned copper is copper with a thin metal tin coating on the surface. Tin mainly plays the role of protecting copper, preventing copper from being oxidized to form patina affecting electrical conductivity. At the same time, tin has a low melting point, easy to weld, and good conductivity. It can also be used as a terminal with chrome plated copper.

Diode

A diode has the property of a single conductor. Diodes can be divided into rectifier diodes, fast diodes, voltage regulator diodes and light emitting diodes.

Commonly used cables have copper or tinned copper conductors inside and two protective layers outside, namely polyvinyl chloride (PVC) insulation layer and PVC sheath. Photovoltaic cables also need irradiation cross-linked polyolene insulation layer and irradiation cross-linked polyolene sheath in addition to conductors. The inside of the photovoltaic cable is a copper wire with a cross-sectional area of 4mm2. If the nominal current of the solar panel (less than 10 amps) is calculated, 2.5mm2 copper wire is sufficient. However, considering that the solar panel often works under high temperature conditions, the cable capacity is reduced, and the system current is relatively large, so a copper wire with a larger cross-sectional area should be used to ensure the safety of the system.

Connectors can be blocked or isolated between circuits, bridging the current flow, so that the circuit to achieve a predetermined function. A pair of connectors consists of one male and one female, using PPO as insulation material. The male connector is used for the positive terminal of the assembly, and the female connector is used for the negative terminal.

Pouring sealant

Many photovoltaic junction boxes use silicone potting adhesives to protect their internal devices and improve heat dissipation.

Function of photovoltaic junction box

MPPT

The maximum power tracking technology and control device are configured for each panel by software and hardware, which can maximize the possibility of power generation efficiency reduction caused by different panel array characteristics, reduce the "barrel effect" on power station efficiency, and can greatly improve the power generation of the power station.

Intelligent shutdown function under abnormal conditions such as fire

In case of fire, the software algorithm built into the junction box will cooperate with the hardware circuit to judge whether there is any abnormality within 10 milliseconds, and take the initiative to cut off the connection between each panel, and reduce the voltage of 1000V to about 40V acceptable to the human body to ensure the safety of fire fighters.

If you have more questions or need more information, please contact us and our professional team will be happy to support and answer you.

You can also contact us directly in the following ways: visit, telephone, email